1.1. Introduction to Quality Management

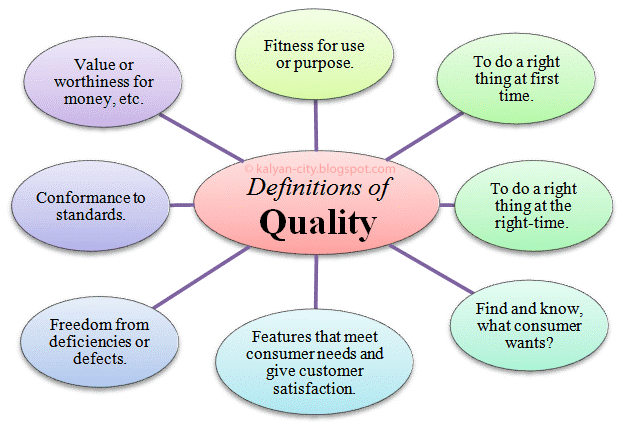

Quality

The totality of features and characteristics of a product or service that bear on its ability to satisfy stated or implied needs

When projected on analytical work, quality can be defined as “delivery of reliable information within an agreed span of time under agreed conditions, at agreed costs, and with necessary aftercare”. The “agreed conditions” should include a specification as to the precision and accuracy of the data which is directly related to “fitness of use” and which may differ for different applications. Yet, in many cases the reliability of data is not questioned and the request for specifications omitted. Many laboratories work according to established methods and procedures which are not readily changed and have inherent default specifications. Moreover, not all future uses of the data and reports can be foreseen so that specifications about required precision and accuracy cannot even be given. Consequently, this aspect of quality is usually left to the discretion of the laboratory. However, all too often the embarrassing situation exists that a laboratory cannot evaluate and account for its quality simply because the necessary documentation is lacking.

Tasks

Watch this video to gain more insight into quality:

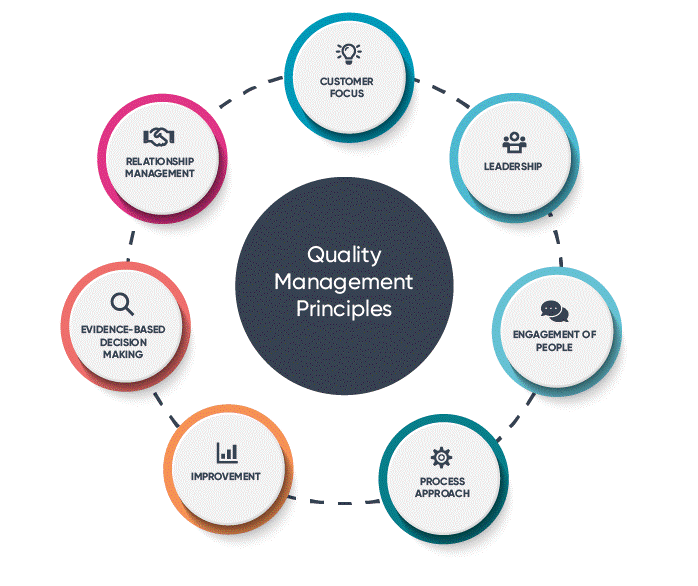

In the ensuing discussions numerous activities aimed at maintaining the production of quality are dealt with. In principle, three levels of organisation of these activities can be distinguished. From the top down these levels are:

- 1. Quality Management (QM)

- 2. Quality Assurance (QA)

- 3. Quality Control (QC)

Quality Management

Is the assembly and management of all activities aimed at the production of quality by organizations of various kinds

Tasks

Watch this video to gain more insight into quality management:

Proper Quality Management implies consequent implementation of the next level: Quality Assurance. The ISO definition reads: “the assembly of all planned and systematic actions necessary to provide adequate confidence that a product, process, or service will satisfy given quality requirements.” The result of these actions aimed at the production of quality, should ideally be checked by someone independent of the work: the Quality Assurance Officer. In case of special projects, customers may require special quality assurance measures or a Quality Plan.

Quality Assurance

The assembly of all planned and systematic actions necessary to provide adequate confidence that a product, process, or service will satisfy given quality requirements

Tasks

Watch this video to gain more insight into quality assurance:

A major part of the quality assurance is the Quality Control defined by ISO as “the operational techniques and activities that are used to satisfy quality requirements. “ An important part of the quality control is the Quality Assessment: the system of activities to verify if the quality control activities are effective, in other words: an evaluation of the products themselves.

Quality Control

The operational techniques and activities that are used to satisfy quality requirements

Quality control is primarily aimed at the prevention of errors. Yet, despite all efforts, it remains inevitable that errors are be made. Therefore, the control system should have checks to detect them.

- what error was made?

- where was it made?

- when was it made?

- who made it?

- why was it made?

Only when all these questions are answered, proper action can be taken to correct the error and prevent the same mistake being repeated.

Tasks

Watch this video to gain more insight into quality control:

Instrument performance check.

Check of calibration or standardization.

Batch control (control sample, identity check).

Overall check (external checks: reference samples, interlaboratory exchange programmes).

Because the first two control levels both apply to the correct functioning of the instruments they are often taken together and then only three levels are distinguished. This designation is used throughout the present Guidelines:

- First-line control:Instrument check / calibration.

2. Second-line control: Batch control

3. Third-line control: External check

It will be clear that producing quality in the laboratory is a major enterprise requiring a continuous human effort and input of money. The rule-of-fist is that 10-20% of the total costs of analysis should be spent on quality control. Therefore, for quality work at least four conditions should be fulfilled:

- means are available (adequate personnel and facilities)

- efficient use of time and means (costs aspect)

- expertise is available (answering questions; aftercare)

- upholding and improving level of output (continuity)

In quality work, management aspects and technical aspects are inherently cobbled together and for a clear insight and proper functioning of the laboratory these aspects have to be broken down into their components. This is done in the ensuing chapters of this manual.